Coating

External Coatings

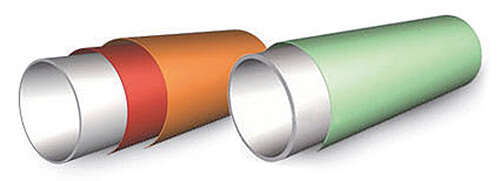

Fusion Bonded Epoxy Coating

FBE coatings are thermoplastically hardening layers of epoxy resin applied to steel pipes using an electrostatic process, and which protects them against corrosion.

FBE can be applied at service temperatures of up to 110 degrees Celsius; the typical thickness is 350 to 450 micrometres. A second layer creates an excellent resistance to damage for the pipeline itself, even under the most difficult environmental conditions.

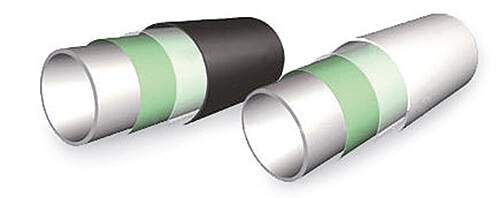

External 3-Layer Polyolefin Coatings

3-layer polyolefin coatings are applied to steel pipes as a combination of thermoplastically hardening resins, copolymer bonding agents and thermoplastics in order to ensure protection against rust and mechanical damage.

Internal Coatings

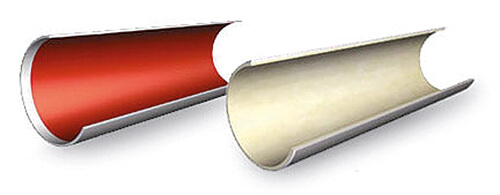

Coatings that Increase the Efficiency of Flow-rate

Liquid epoxy resin is sprayed on the inside of the pipes at a typical thickness of 60 to 100 micrometres. The result is an improvement of the gas transportation capacity, a minimization of frictional resistance and thus a reduction in compressor stations. Simplified cleaning and temporary protection against rust make flow coating a unique and cost-efficient solution for gas transportation.

Liquid Epoxy Resin Coatings for Water Pipelines

Liquid epoxy resin is sprayed on the insides of the pipes at thicknesses between 400 and 500 micrometres. For this we use a new generation of solvent-free epoxy resins.